Peanuts Paste Filling Machine Supplier

- Model

- FM016

Item specifics

- Packaging products

- paste

- Filling specification

- 100-500ML

- Hopper size

- 150L(304 stainless steel )

- Machine power

- 2.5Kw

Review

Description

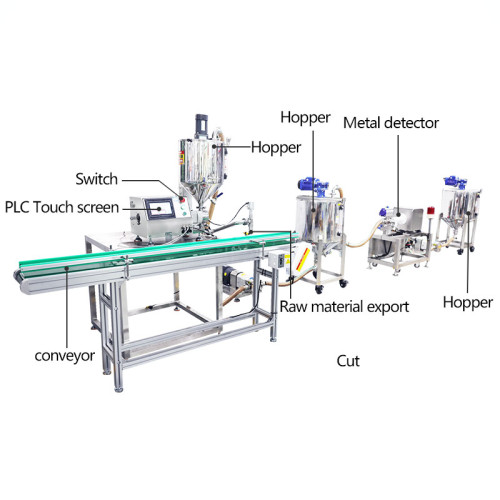

Introduction of Peanuts Paste Filling Machine

Hereby are some key features for peanuts paste filling machine

1. Core Design Features Targeting Material Characteristics

High Viscosity Adaptability: A key feature is its ability to effectively handle materials with poor flowability and high adhesion, such as peanut butter. Specialized conveying and filling systems (e.g., piston and screw types) ensure stable and continuous material delivery.

Particle Handling Capability: For peanut butter containing particles, the filling system's valves, pipes, and pumps are specially designed to ensure particle integrity, preventing shearing and breakage, and preventing particle blockage.

Anti-Drip Design: Filling nozzles typically feature back-suction or anti-drip functions to prevent high-viscosity materials from stringing or dripping after filling, keeping the packaging opening and exterior clean.

2. Key Technical and Performance Characteristics

High-Precision Filling: Utilizing servo motors or high-precision pneumatic control ensures consistent filling weight or volume for each bottle/can, with an accuracy typically ranging from ±0.5% to ±1%, meeting national metrological standards and reducing material waste.

Wide Applicability: By changing a few parts (such as the filling head and piston cylinder), it can be used with containers of different sizes and shapes (glass bottles, plastic bottles, wide-mouth jars, etc.), and with different capacities ranging from tens of grams to several kilograms.

Automation and High Efficiency: Fully automatic models can achieve continuous operation of "automatic bottle positioning -> quantitative filling -> automatic discharging." When connected with capping machines and labeling machines, it can form a complete production line, significantly improving production efficiency.

Easy to Clean and Maintain (CIP/SIP): Parts of the equipment that come into contact with materials typically use quick-connect clamps for easy disassembly and cleaning. Many modern models support CIP (Cleaning in Place), allowing for cyclic cleaning without complete disassembly, meeting food hygiene and safety standards (such as HACCP and GMP).

3. Structural and Material Characteristics

Food-Grade Contact Materials: All parts that come into contact with peanut butter (such as hoppers, pipes, piston cylinders, and filling valves) are made of 304 or 316 stainless steel, which is corrosion-resistant, non-toxic, and easy to clean, meeting food hygiene requirements.

Modular Design: The equipment has a compact structure, with key modules (such as the filling head, drive system, and control system) relatively independent, facilitating fault diagnosis, maintenance, and future functional upgrades.

User-Friendly Operation: Equipped with a human-machine interface (touchscreen), it allows for easy setting of parameters such as filling volume and speed, storage of multiple recipes, and intuitive and simple operation.

4. Characteristics of Common Filling Methods (Peanut butter mainly uses the following two):

Piston Filling:

Advantages: Extremely high precision, best adaptability to highly viscous, large-particle materials, and stable speed. It is the most classic and reliable method for peanut butter filling.

Principle: A cylinder pushes a piston to move within the cylinder, achieving quantitative material intake and discharge.

Screw Filling:

Advantages: Ideal for extremely viscous, almost non-flowing materials (such as pastes). The material is pushed by the rotation of the screw, with very precise control and almost no residue.

Principle: The feeding amount is determined by precisely controlled screw rotation.