Seal Machine for Food Paste Packing Machine Supplier

- Model

- FM015

Item specifics

- Packaging products

- paste

- Filling specification

- 100-500ML

- Hopper size

- 150L(304 stainless steel )

- Machine power

- 2.5Kw

Review

Description

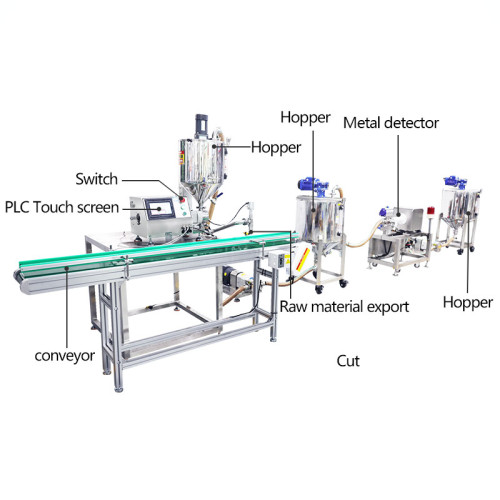

Introduction of Seal Machine for Food

seal machine for food/Paste filling machines are automated equipment specifically designed for filling paste-like and semi-fluid materials (such as cosmetics, pharmaceuticals, food, and chemical products). They feature the following key characteristics:

1. High-Precision Filling

Accurate Metering: Employing volumetric, gravimetric, or servo control technology, consistent filling volume and minimal error (typically controllable within ±0.5%~1%) are ensured.

Adaptability to Different Viscosities: Adaptable to filling everything from emulsions to high-viscosity pastes (such as toothpaste and ointments) by adjusting pump pressure, valves, or changing filling heads.

2. Anti-Drip Design

Special Filling Valves: Equipped with anti-drip nozzles or back-suction functions to prevent material residue from contaminating the bottle opening or equipment.

Easy Cleaning: Some valves can be quickly disassembled for easy cleaning and maintenance.

3. Strong Material Compatibility

Corrosion-Resistant Materials: Key components (such as hoppers, pipes, and filling heads) are often made of stainless steel (304/316L), food-grade plastics, or special coatings, complying with GMP/FDA standards.

Pollution-Proof Design: The closed system reduces external contamination, suitable for sterile or cleanroom environments.

4. Automation and Intelligence

Automated Operation: Can be linked with conveyor belts, capping machines, labeling machines, etc., to form a production line, reducing manual intervention.

Human-Machine Interface (PLC/HMI): Touchscreen for setting parameters (filling volume, speed), supporting data storage and fault diagnosis.

Customizable: Clamping mechanism can be adjusted according to bottle shape (tube, can, bottle) to adapt to various containers.

5. High-Efficiency Production

High-Speed Filling: Multi-station design (e.g., dual-head, four-head filling) improves efficiency, reaching tens to hundreds of bottles/minute.

Quick Changeover: Molds or filling heads can be quickly changed, adapting to small-batch, multi-variety production.

6. Safety and Environmental Protection

Safety Devices: Equipped with emergency stop buttons, safety guards, etc., meeting mechanical safety standards.

Environmentally Friendly Design: Reduces material waste; some equipment is equipped with a waste recycling system.